Cross Flow Plate Heat Exchanger

- NEW ROC

- China

- 7-15days

- 5,000 production per day

Cross Flow Plate Heat Exchangers accommodate viscous fluids or those containing fibrous materials or larger particles. Wide-channeled horizontal ribbed pattern with no metal-to-metal contact allows Cross Flow of particles that can block other heat exchangers.

In many ways, Cross Flow Heat Exchangers are similar in function to conventional plate heat exchangers.

However, their distinctive engineering and construction makes them ideal for specialized applications. They are used in pulp and paper production; processing of beet sugar; beer mash processing at breweries; and sludge processing, which includes a gamut of applications such as quenching oil, plating solutions, and work with crystals. Food processors use free-flow heat exchangers for heating and cooling in grain processing. The units are also used in producing ethanol and in textile mills.

They are suitable for many heating, cooling and heat recovery applications in a wide range of industries. Despite their specialized construction,  the units can easily be disassembled to replace gaskets or to take care of other maintenance. And like other products, they are also highly efficient, reliable, and easy to operate.

the units can easily be disassembled to replace gaskets or to take care of other maintenance. And like other products, they are also highly efficient, reliable, and easy to operate.

Professional plate heat exchanger manufacturer We can not only provide you with PHE, but also we can design the appropriate plan for heating exchange according to your need. We have 15- year experience of designing in this field and solve various problems for you.We have a wealth of HVAC, refrigeration, metal steel,marine engineering, paper, power,hemical, marine engineering, food and beverage experience.

Our Advantages:

1. Manufacturer and Distributer, we can supply different brands and series plate and gasket, such as Alfa-Lava, APV, GEA, Tranter, SONDEX etc.

2. As manufacturer, we can supply the best quality replace parts for above brands to help you save more cost.

3. Over 15 years' experience in the energy field, we also can provided technical service such as technical consultation, equipment upgrade, capacity expansion scheme, maintenance and cleaning of the equipment.

4. High quality with competitive price, global fast delivery.

5. Our products are superior quality and environment friendly.

6. Prompt response to inquiries and orders.

7. Inventory for standard products.

Working principles

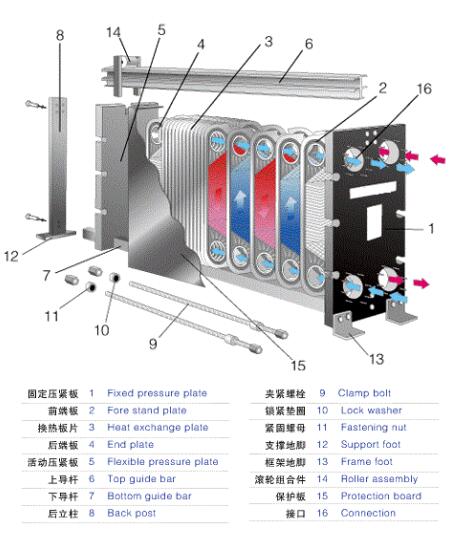

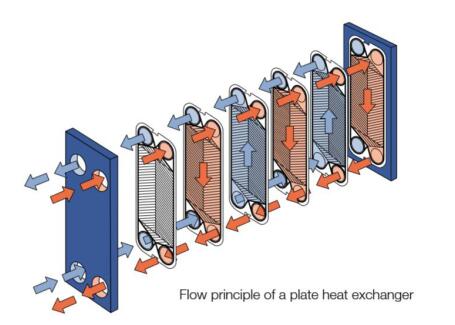

The plate heat exchanger is composed of a group of corrugated metal plates with holes on the plates, through which two liquids for heat transfer pass. The sheet metal is mounted in a frame with a fixed plate and a movable compaction plate on the side and clamped with clamping bolts. A sealing gasket is mounted on the plate to seal the fluid passage and guide the fluid to flow alternately into the respective passages. Fluid flow, physical properties, pressure drop and temperature difference determine the number and size of plates. The corrugation of the plate not only improves the turbulence degree, but also forms many supporting points, which can withstand the pressure difference between the media. The metal plate and the movable compaction plate are suspended on the guide rod and positioned by the lower guide rod, while the end of the rod is fixed on the support rod, but if one or two liquids pass through the heat exchanger more than once, the interface should be opened on the fixed plate and the movable compaction plate. In most cases, the use of one-way, all pipelines are connected to the fixed pressure plate, check the removal of heat exchangers, do not have to remove the pipeline.

Standard Materials

For Frame: Carbon steel, stainless steel,

For Plate: Stainless stell ,titanium Plates Stainless steel alloy304,Stainless steel alloy316 Stainless steel alloy C276 or Titanium or SMO

For Gaskets: NBR , EPDM , Viton A, Viton G CR

Why choose Gasketed Plate Heat Exchanger?

* High heat transfer efficiency

* Low pressure lose

* Compact structure

* Easy assembly & disassembly

* Sensitive temperature control

* High operating flexibility

* Long life-time

Application

Food industry: Milk pasteurization Milk and beverage pasteurization, Wine tempering, Bottled water treatment, CIP (Cleaning-in-Place) heating, Reverse osmosis water.

Marine application: Central cooling of the main or auxiliary engines or turbines, Lubrication oil cooling, Recooling of circulated water for cooling cylinders, pistons, injection nozzles, Cooling of Baoder oil, compressor oil and other lubricants, Preheating of lubrication oil and heavy fuel oil, Preheating of seawater for fresh water production, Heat recovery, Heat exchange to air-condition the passengers' cabins and freight spaces

Others: Turbine oil cooler, Chemical industry, district heating, district cooling, swimming pool heating, solar heating.