OEM & ODM For Plate Heat Exchanger Plate

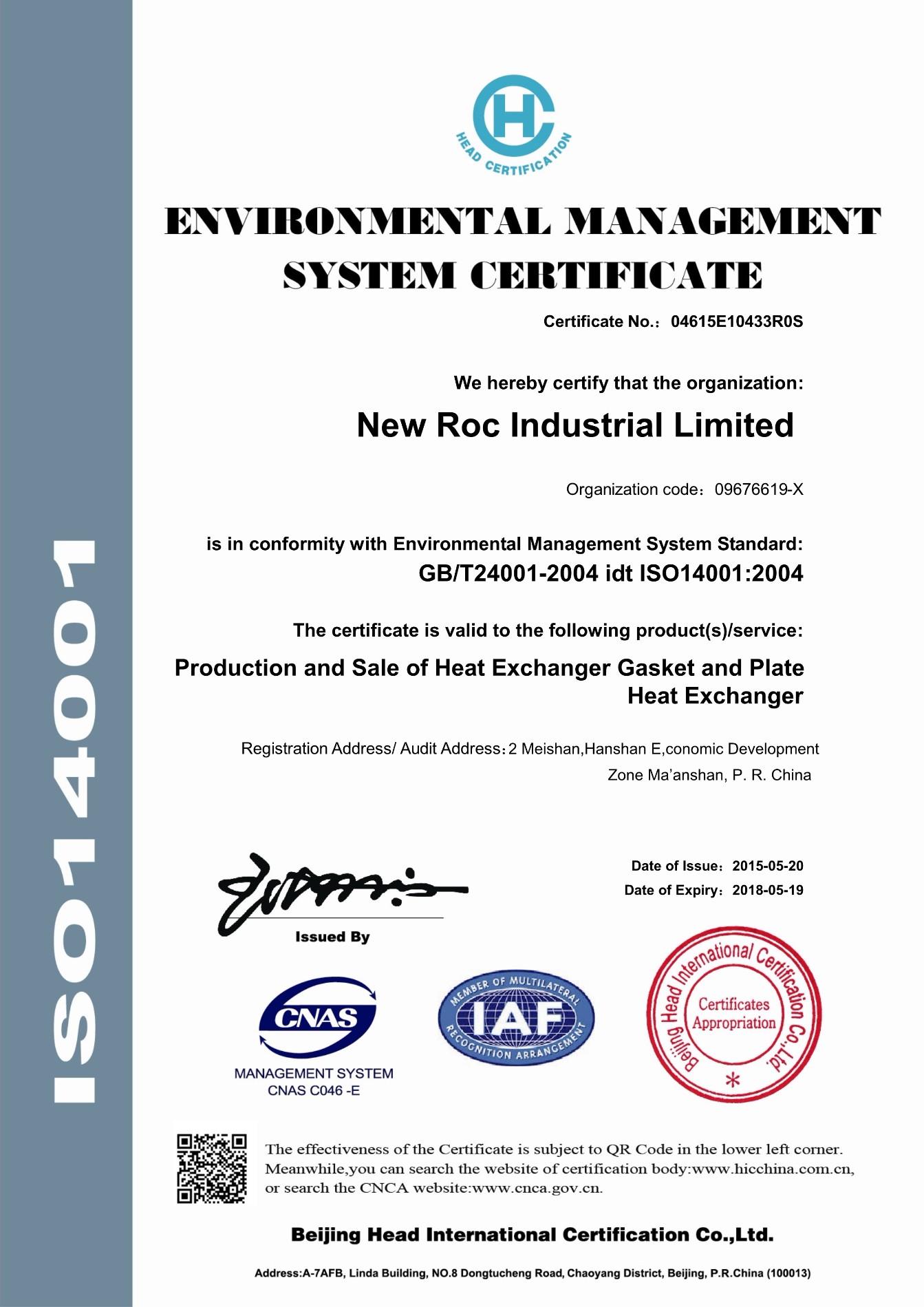

- NEW ROC

- China

- 7-15days

- 5,000 production per day

Heat transfer plates are characterized by optimum embossing, resulting in high heat transfer coefficients. Variable flow gaps can be generated as a result of the different types and angles of embossing. This permits optimum adaptation to the respective application conditions.

We can supply a large range of high quality heat exchanger plate for many brands. These plates can be exchanged with original plates, and are already widely used in after service strictly controls the production and strict delivery inspection. We strictly enforce the requirements of ISO9000, and strictly control every aspect of production, so that each heat exchanger plate can be traced back.

NEW ROC supplies high quality plate heat exchanger spares, including plate replacement for plate and frame heat exchanger or gasketed plate heat exchangers.

The gaskets and plates are specified to fit most plate heat exchanger manufacturing and replacement models.

The Standard Materials

304 Stainless Steel

This is the lowest cost heat transfer plate material. It has low corrosion resistance and is usually only available in a thickness of 0.4mm. This type of heat transfer plate is typically used in HVAC applications.

316 Stainless Steel

This is the most common heat transfer plate material and is used in many applications. 316 stainless steel has a high corrosion resistance and is typically available in thickness from 0.4mm to 0.8mm.

Titanium

This type is very resistant to chemical attack, including most acids, chloride, seawater and chlorine chemicals. The thickness of titanium is usually from 0.5 mm to 0.6 mm.

Hastelloy C276

Other common names: Alloy C276, Hastelloy C, Inconel® C-276 Hastelloy C-276.

Hastelloy C276 is a nickel-molybdenum-chromium superalloy with tungsten added for excellent corrosion resistance in a variety of harsh environments. Alloy C-276 is widely used in the harshest environments such as chemical processing, pollution control, pulp and paper production, industrial and municipal waste treatment, and acid natural gas recovery. The thickness can range from 0.6mm to 0.8mm.

SMO 254

Sandvik 254 SMO is a high-alloy austenitic stainless steel developed for use in seawater and other aggressive chloride-bearing media. Thickness available from 0.6mm to 0.8mm.