Plate Heat Exchanger For Coal Chemical Industry

- NEW ROC

- China

- 7-15days

- 5,000 production per day

Mostpowerstationsburnmanymillionsoftonsofcoalperyearwhichcancomeinvariousformsand qualityfromverydirtycoalinsomeregionstoverypurecoalinothers.Thisdictatestheheatproduced andtheplantandequipmentneededtooptimiseuseoftheheat.Evenwheresuppliesofcoalareabundant, thereisstillaneedtouseitefficientlyandtolookatways thatenergyproducedasaresultofitsburning maybereused.

A waste heat recovery unit/heat exchanger recovers heat from hot streams, gasses that still have relatively high energy content in them. This  would otherwise go unused into the atmosphere. Obviously waste heat recovery comes with a capital cost for the design and manufacture of the system and the various solutions on the market need to be assessed in terms of their track record in meeting the specific needs of the coal industry. However, taking steps to determine whether a valuable heat source can be used rather than wasted is always worth the effort.

would otherwise go unused into the atmosphere. Obviously waste heat recovery comes with a capital cost for the design and manufacture of the system and the various solutions on the market need to be assessed in terms of their track record in meeting the specific needs of the coal industry. However, taking steps to determine whether a valuable heat source can be used rather than wasted is always worth the effort.

Our Advantages:

1. Manufacturer and Distributer, we can supply different brands and series plate and gasket, such as Alfa-Lava, APV, GEA, Tranter, SONDEX etc.

2. As manufacturer, we can supply the best quality replace parts for above brands to help you save more cost.

3. Over 15 years' experience in the energy field, we also can provided technical service such as technical consultation, equipment upgrade, capacity expansion scheme, maintenance and cleaning of the equipment.

4. High quality with competitive price, global fast delivery.

5. Our products are superior quality and environment friendly.

6. Prompt response to inquiries and orders.

7. Inventory for standard products.

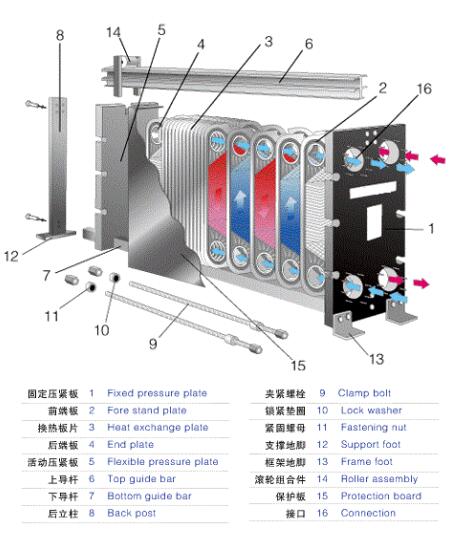

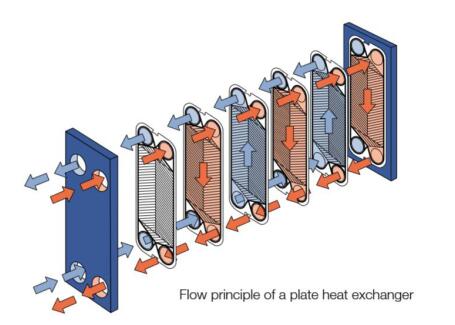

Working principles

Heat exchanger is an equipment which reduces the temperature of a medium by transferring temperature of that medium to another, when both the mediums are separated by a solid membrane or wall like structure. For efficient operation, the surface area of the wall which separates the two mediums is maximized, simultaneously minimizing the flow resistance of the fluid.Channels are formed between the plates and corner ports are arranged so that the two media flow through alternate channels. The heat is transferred through the thin plate between the channels, and complete counter current flow is created for highest possible efficiency.No intermixing of the media or leakage to the surroundings will take place as gaskets around the edges of the plates seal the unit. The corrugation of the plates provides a suitable passage between the plates, support of each plate against the adjacent one and a strong turbulence resulting in maximum heat transfer efficiency.

Standard Materials

For Frame: Carbon steel, stainless steel,

For Plate: Stainless stell ,titanium Plates Stainless steel alloy304,Stainless steel alloy316 Stainless steel alloy C276 or Titanium or SMO

For Gaskets: NBR , EPDM , Viton A, Viton G CR

Why choose Gasketed Plate Heat Exchanger?

* High heat transfer efficiency

* Low pressure lose

* Compact structure

* Easy assembly & disassembly

* Sensitive temperature control

* High operating flexibility

* Long life-time

Application

Food industry: Milk pasteurization Milk and beverage pasteurization, Wine tempering, Bottled water treatment, CIP (Cleaning-in-Place) heating, Reverse osmosis water.

Marine application: Central cooling of the main or auxiliary engines or turbines, Lubrication oil cooling, Recooling of circulated water for cooling cylinders, pistons, injection nozzles, Cooling of Baoder oil, compressor oil and other lubricants, Preheating of lubrication oil and heavy fuel oil, Preheating of seawater for fresh water production, Heat recovery, Heat exchange to air-condition the passengers' cabins and freight spaces

Others: Turbine oil cooler, Chemical industry, district heating, district cooling, swimming pool heating, solar heating.